JXQ-10D (Simple type) Specifications: | 1. Gas output: 10m3/h 2. Gas caloric value: 1000-1200Kcal/m3 3. Gasification efficiency :>72% 4. Power supply: 220V50Hz 5. Material Feeding consumption: 5KG/H 6. Certificate: CE 7. Raw material requirements: length size |

JXQ-10A (Simple type) Specifications: | 1. Gas output: 10m3/h 2. Gas caloric value: 1000-1200Kcal/m3 3. Gasification efficiency :>72% 4. Power supply: 220V50Hz 5. Material Feeding consumption: 5KG/H 6. Certificate: CE 7. Raw material requirements: length size |

JXQ-30A (Simple type) Specifications: | 1. Gas output: 30m3/h 2. Gas caloric value: 1000-1200Kcal/m3 3. Gasification efficiency :>72% 4. Power supply: 220V50Hz 5. Material Feeding consumption: 15-18KG/H 6. Certificate: CE 7. Raw material requirements: length size |

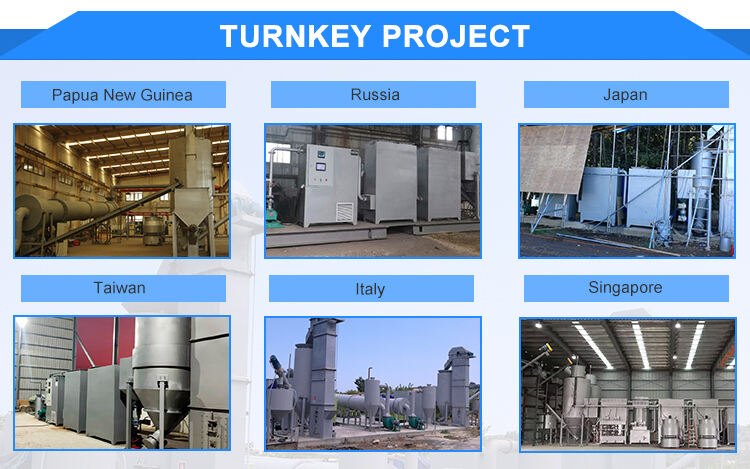

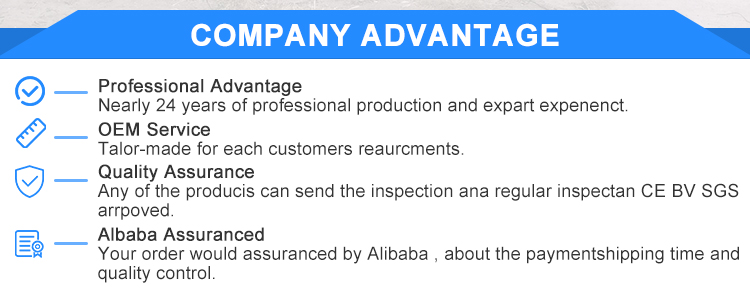

Why Choose Us

Why Choose Us

KEXIN

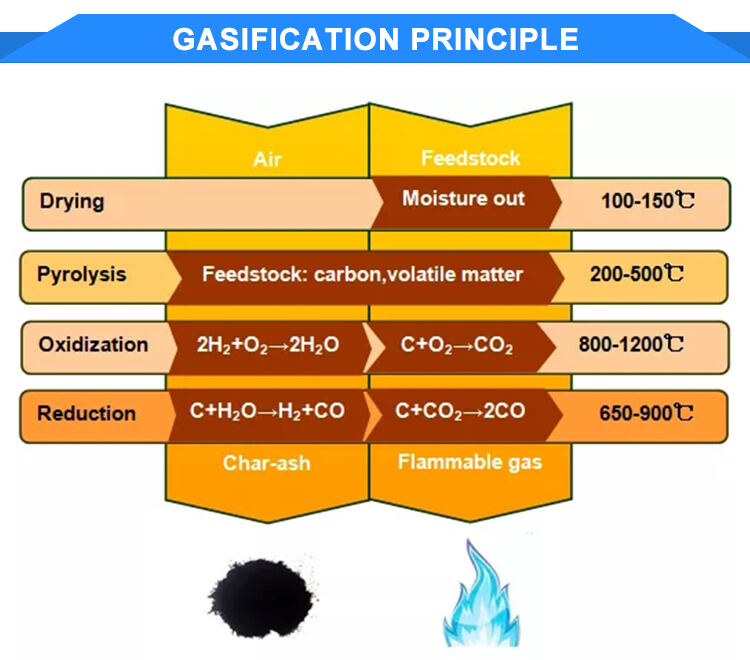

Launching the small gasifier is a forward thinking equipment that is perfect for generating timber gasoline through pyrolysis. Our mini biomass gasifier is designed with your energy-saving needs in mind. The KEXIN pyrolysis plant is not just effective but additionally efficient, rendering it perfect for domestic and commercial usage.

The KEXIN gasifier uses lumber as its main fuel supply. This product converts wood into gas through pyrolysis, making it an exceptional source which is sustainable. Our energy saving gear is just an alternative perfect for traditional fossil fuels that are getting increasingly expensive and unsustainable.

Our mini biomass gasifier is sized to generally meet the requirements of a family group making it a great choice for home owners who want to lower their energy bills while reducing their carbon footprint. It is usually perfect for small-scale businesses that are looking to use without depending on grid power.

The KEXIN pyrolysis plant is rated at 2.5kW and may produce as much as 500 liters of lumber fuel each hour. The product was created with top-notch materials being durable. It is developed to withstand temperatures that are high in the harsh conditions that come with biomass gasification.

Our KEXIN small gasifier is certainly not difficult to place in and operate, also it features a manual user-friendly guides you through the installation procedure. These devices can be very easy to keep, therefore you will likely not want to worry about extra cash in repairs.

The KEXIN mini biomass gasifier is eco-friendly helping reduce greenhouse gasoline emissions, making it an investment very good anyone who's worried about the environmental surroundings. It's also affordable, which means you do not need to break your allowance to take pleasure from the benefits of energy saving equipment.

Copyright © Qingdao Kexin New Energy Technology Co., Ltd. All Rights Reserved - Blog - Privacy Policy